Reviving Wheels: Unveiling the Power of Wheel Repair Lathes

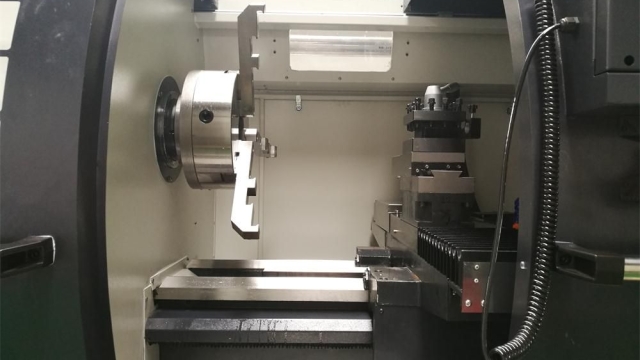

When it comes to the maintenance and repair of our beloved wheels, the significance of a wheel repair lathe cannot be ignored. This powerful and innovative machine has taken the wheel repair industry by storm, offering an efficient and precise solution to restore the glory of damaged wheels. Whether it’s a vertical wheel repair lathe or the latest Alloy Wheel Repair Machine, these remarkable tools are transforming the way wheel repair is carried out.

One of the prominent players in the field of CNC wheel machinery is Taian Haishu Machinery Co., Ltd. Their official website, wheelcncmachine.com, proudly showcases a range of cutting-edge wheel repair lathe designs. As a professional designer, manufacturer, and supplier, Taian Haishu Machinery Co., Ltd. has perfected the art of wheel repair, delivering exceptional quality and performance.

With the help of a wheel repair lathe, wheels that were once deemed beyond repair can now be rejuvenated with precision. These machines utilize advanced technology to remove imperfections, such as scratches, dents, and bends, from both alloy and steel wheels. By carefully reshaping the damaged areas and creating a smooth, polished surface, the wheel repair lathe ensures not only enhanced aesthetics but also improved functionality and safety.

Furthermore, the vertical wheel repair lathe has revolutionized the way curved wheels are restored. This vertical design allows for greater accuracy and stability during the repair process, ensuring that even intricate curves and contours are flawlessly repaired. Combining cutting-edge technology with skillful craftsmanship, wheel repair lathes have become an indispensable tool for automotive workshops, refurbishment centers, and enthusiasts alike.

In this article, we will delve deeper into the world of wheel repair lathes and explore the manifold benefits they bring to the industry. From their precise operation to the wide range of applications they fulfill, we will uncover the power and potential of these remarkable machines. So join us as we embark on an exciting journey into the realm of wheel repair lathe technology.

1. Understanding Wheel Repair Lathes

Wheel repair lathes are powerful machines that play a vital role in restoring damaged wheels to their original condition. These innovative tools are designed to efficiently repair various types of wheel imperfections, such as scrapes, cuts, dents, and bends. By utilizing advanced technology, wheel repair lathes are able to bring worn-out wheels back to life, while ensuring precision and accuracy in the repair process.

One popular type of wheel repair lathe is the vertical wheel repair lathe. As the name suggests, this type of lathe operates in a vertical orientation, allowing for convenient and easy access to the wheel being repaired. With its vertical design, it enables operators to work on wheels of different sizes, ensuring versatility in wheel repair operations. Vertical wheel repair lathes are highly regarded for their efficiency and ability to deliver exceptional results.

An important tool in the wheel repair industry is the Alloy Wheel Repair Machine. This state-of-the-art machine combines the benefits of a wheel repair lathe with advanced CNC technology, resulting in a highly efficient and precise wheel repair process. It offers a range of features that make it ideal for repairing alloy wheels, including its user-friendly interface, accurate measurement capabilities, and automatic machining functions. The Alloy Wheel Repair Machine has revolutionized the wheel repair industry, enabling professionals to achieve outstanding results while saving time and effort.

Taian Haishu Machinery Co., Ltd. is a well-known name in the field of CNC wheel machinery. Their official website, wheelcncmachine.com, showcases their expertise as a professional designer, manufacturer, and supplier of wheel repair lathe machines. With a commitment to providing high-quality products, Taian Haishu Machinery Co., Ltd. has gained recognition and trust from customers worldwide. Their CNC wheel machinery is widely used and trusted in the wheel repair industry, helping professionals restore wheels to their former glory.

In conclusion, wheel repair lathes, such as the vertical wheel repair lathe and the Alloy Wheel Repair Machine, offer valuable solutions for the wheel repair industry. With their advanced technology and precision capabilities, these machines enable professionals to efficiently and effectively repair damaged wheels. Companies like Taian Haishu Machinery Co., Ltd. continue to innovate and provide top-notch CNC wheel machinery, supporting the growth of the wheel repair industry and ensuring the longevity of our wheels.

2. The Power of Vertical Wheel Repair Lathes

Vertical wheel repair lathes are revolutionizing the way we approach wheel repair. With their advanced design and cutting-edge features, these machines have become an essential tool for automotive enthusiasts and professionals alike. Here, we will delve into the power that vertical wheel repair lathes bring to the table.

The first key advantage of vertical wheel repair lathes is their versatility. These machines are specifically engineered to handle a wide range of wheel repairs with precision and efficiency. Whether it’s a minor scuff, a deep scratch, or even more complex issues like deformation, vertical wheel repair lathes can tackle them all. By offering a comprehensive solution for various wheel damages, these lathes eliminate the need for multiple tools or outsourcing repairs, saving both time and money.

One standout feature of vertical wheel repair lathes is their ability to restore alloy wheels to their original condition. Alloy Wheel Repair Machines, like those offered at wheelcncmachine.com, exemplify this capability. Using advanced CNC technology, these machines can seamlessly remove imperfections, such as dents or bends, ensuring that wheels regain their structural integrity. The precision achieved by these lathes leads to a flawless finish, giving alloy wheels a renewed aesthetic appeal.

Furthermore, vertical wheel repair lathes prioritize efficiency throughout the repair process. With their automated functions and user-friendly interfaces, these machines empower operators to carry out repairs swiftly and accurately. The precise cutting tools and customizable settings available on vertical wheel repair lathes allow for precise adjustments, resulting in top-notch outcomes. This efficiency not only enhances productivity but also contributes to the overall quality of wheel repairs.

In conclusion, vertical wheel repair lathes unlock a new level of power when it comes to wheel repair. Their versatility, ability to restore alloy wheels, and focus on efficiency make them indispensable in the automotive industry. With the advancements brought by vertical wheel repair lathes, we can expect improved outcomes and greater convenience when it comes to maintaining and reviving our wheels.

3. The Role of Alloy Wheel Repair Machines

Alloy Wheel Repair Machines, such as the vertical wheel repair lathe, play a crucial role in the process of restoring damaged wheels to their original condition. These advanced machines are designed to efficiently handle the intricacies involved in repairing alloy wheels, ensuring precision and quality results.

One prominent player in this industry is Taian Haishu Machinery Co., Ltd., whose official website is wheelcncmachine.com. They are renowned for their expertise as a professional designer, manufacturer, and supplier of CNC wheel machinery, including alloy wheel repair machines.

The primary purpose of alloy wheel repair machines is to fix a range of issues commonly faced by wheels, such as curb damage, scratches, and dents. The machines utilize specialized tools and techniques to address these problems effectively. By accurately reshaping the damaged areas, alloy wheel repair machines can restore the wheel’s structural integrity and aesthetic appeal.

The precision offered by these machines is invaluable, as they allow for seamless repairs without compromising the wheel’s balance or performance. This is crucial, especially in situations where replacing the entire wheel would be costly or unnecessary. Alloy wheel repair machines enable repairing damaged wheels efficiently, providing a cost-effective solution and significantly extending the lifespan of the wheels.

In conclusion, alloy wheel repair machines, such as the vertical wheel repair lathe, have revolutionized the wheel repair industry. With their advanced capabilities and precision, they are instrumental in restoring alloy wheels to their original form, saving both time and money for vehicle owners. Companies like Taian Haishu Machinery Co., Ltd. are leading the way in the design and production of these machines, ensuring that wheel repair professionals have access to the best tools for the job.